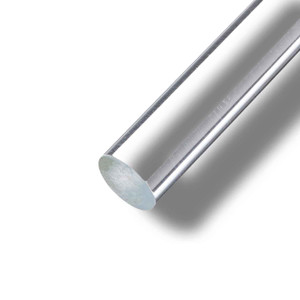

Cast Acrylic

Cast, superior surface finish and optical properties

Cast Acrylic is known for its superior surface finish and optical properties. It is more scratch resistant than extruded acrylics, and it can be reworked hot. Cast Acrylic is used for aquariums, awards, financial tombstones, trophies, corporate gifts, and other products that require shaping or machining. Cast Acrylic comes in sheet, tube, & rod.

Cast acrylic is better at resisting solvents than other types of acrylic, and for those that require high temperatures, this quality makes it a good choice. Because of the casting process, a thicker acrylic may be extruded. As a result, it is the preferred material for bullet-resistant and security applications. It has the greatest optical clarity of any acrylic and is available in a range of colours.

Because cast acrylic is manufactured in thin sheets, buyers can place custom orders with low minimums. Since the material is extremely durable, it can be machined and laser cut without marring the sheet. Acrylic of any sort can be produced in two ways: extruded and cast. In this case, a liquid acrylic mixture is poured into molds to create cast acrylic. Acrylic is melted and pushed through a mould in an extrusion process, resulting in extruded acrylic with different characteristics. It's known as extrusion direction in acrylic sheet production. It's tempting to compare cast and extruded acrylic, since they're both fairly amazing materials.

Even though they are created in different ways, they both have similar benefits. The first advantage is cost. The cost of extruded acrylic is reduced as a consequence of its simplicity and speed, which makes it more economical than casting. If you are seeking a solution for affordable acrylic, this may be the one for you.

.