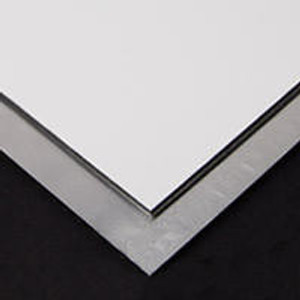

FOME-COR® with ENCORE® TECHNOLOGY - Premium Memory Foam Board

FOME-COR® with ENCORE® TECHNOLOGY represents the next evolution in foam board performance, featuring a proprietary memory polystyrene foam core specially formulated for exceptional resiliency and dent resistance. This innovative substrate maintains its original shape when compressed, making it ideal for high‑traffic displays and applications where durability is essential.

As part of the premium FOME-COR® Collection from 3A Composites, this non‑pillowing foam board combines the lightweight handling and easy fabrication of standard foam board with enhanced performance characteristics that protect your displays from everyday impacts. The bright white, double clay‑coated or black uncoated paper facers provide excellent printability while the specialized core retains clean, open edges when die‑cut or hand‑cut.

How Does FOME-COR® with ENCORE® TECHNOLOGY Differ from Standard FOME-COR®?

- Memory Foam Core: Features specially formulated recovery foam that resists denting and retains its original shape, unlike standard foam that remains compressed.

- Non‑Pillowing Edges: Creates clean, open edges when die‑cut, compared to the compressed, closed edges of standard FOME‑COR®.

- Enhanced Durability: Provides superior resistance to handling damage, maintaining a professional appearance longer in high‑traffic environments.

- Consistent Edge Appearance: Cut edges spring back to their original thickness, maintaining uniform board dimensions and finish quality.

- Superior Dent Resistance: Engineered specifically to withstand impacts and pressure without permanent deformation of the substrate.

Features & Benefits

- Proprietary Memory Foam Core: Specially formulated polystyrene recovery foam maintains its shape even after compression, ensuring displays remain pristine despite handling or accidental impacts.

- Clean, Open Edges: Unlike standard foam board that creates compressed closed edges when die‑cut, ENCORE® TECHNOLOGY provides clean, open edges that maintain consistent thickness throughout the board.

- Exceptional Printability: Bright white, double clay‑coated paper facers provide an optimal surface for both digital and screen printing, delivering vibrant colors and sharp details.

- Lightweight Yet Rigid: Maintains the easy handling and transportation benefits of standard foam board while adding increased durability and performance.

- Environmentally Conscious Sourcing: Paper facers are sourced from suppliers participating in the Sustainable Forestry Initiative (SFI) or Forest Management Certification.

Technical Specifications

| Material Composition | Proprietary memory polystyrene foam core with paper facers |

|---|---|

| Facer Options | Bright white double clay‑coated or black uncoated paper |

| Standard Thicknesses | 3/16″ (4.8 mm), 3/8″ (10 mm), 1/2″ (13 mm) |

| Standard Sheet Sizes | 20″×30″, 24″×36″, 30″×40″, 32″×40″, 40″×60″, 48″×96″ |

| Edge Properties | Non‑pillowing, clean open edges when die‑cut |

| Cutting Properties | Cuts easily with knife, scissors, die‑cutter; maintains open edges |

| Print Compatibility | Digital printing, screen printing, direct printing with various ink types |

| Indoor Use | Indoor applications only |

| Sustainability | Paper facers sourced from SFI or Forest Management Certified suppliers |

Applications of FOME-COR® with ENCORE® TECHNOLOGY

High‑Traffic Retail Displays

- The dent‑resistant properties make FOME-COR® with ENCORE® TECHNOLOGY ideal for retail environments where displays may be frequently touched or bumped by customers.

Die‑Cut Promotional Displays

- Non‑pillowing edges ensure clean, consistent cutouts for intricate shapes and detailed designs.

Trade Show & Exhibition Graphics

- Lightweight yet durable, perfect for multi‑day events where graphics endure frequent handling and transport.

POP/POS Displays

- Enhanced durability ensures messaging remains clear and professional during shipping, installation, and consumer interaction.

Dimensional Signage

- Consistent edge quality and dimensional stability for multi‑layered or 3D signage applications.

Educational & Presentation Boards

- Recovery properties extend usable life by preventing dents and dings from frequent handling.

Printing & Fabrication Capabilities

Printing Options

- Digital Direct Printing: Optimal surface for UV flatbed digital printing, delivering vibrant colors and sharp details.

- Screen Printing: Maintains dimensional stability for accurate registration and print quality.

- Mounting Printed Graphics: Ideal substrate for mounting with added dent resistance.

- Hand‑Finished Applications: Compatible with paints and finishing techniques, protecting against handling damage.

Fabrication Techniques

- Hand Cutting: Clean cuts with knives or scissors, maintaining open edges.

- Die Cutting: Open edges remain uncompressed, allowing precise edge details.

- CNC Routing: Clean edges without crushing, ideal for complex cuts.

- Multi‑Layer Construction: Perfect for dimensional displays with maintained structure and appearance.

Installation & Handling Recommendations

Handling & Storage

- Flat Storage: Store sheets flat to prevent warping.

- Climate Control: Maintain temperature and humidity within recommended ranges.

- Clean Handling: Use gloves to avoid transferring oils or dirt.

Fabrication Guidelines

- Sharp Tools: Use clean, sharp blades for professional edge quality.

- Edge Finishing: Apply edge banding or painting for closed‑edge aesthetics if needed.

- Die‑Cutting Setup: Adjust pressure to cut fully without excessive compression.

Display Mounting

- Mounting Options: Use removable adhesives, Velcro®, or pushpins as appropriate.

- Support Points: Provide adequate backing for larger pieces to prevent sagging.

- Indoor Use Only: Not suitable for outdoor exposure; choose weather‑resistant alternatives for outdoor applications.