Foam Boards

Foam Boards — Foam PVC, Gatorfoam & Paper-Faced Display Boards

Laird Plastics supplies foam boards for signage, retail displays, exhibits, and mounting. Choose foam PVC (often known by brands like Sintra), premium Gatorfoam for extra rigidity, and paper-faced foamboard for lightweight, economical mounting. Available in popular sizes and thicknesses with cut-to-size and fabrication services.

Foam PVC Sheets (Sintra-Style)

Closed-cell PVC with smooth surfaces for direct print, vinyl, or paint. Good dimensional stability and moisture resistance for indoor and certain sheltered outdoor uses. Machines, routs, and thermoforms cleanly.

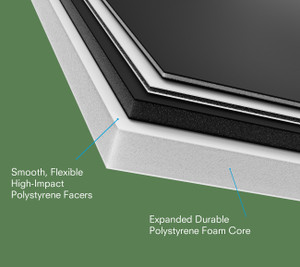

Gatorfoam / Heavy-Duty Foam Board

Polystyrene foam core with dense wood-fiber veneer facers for increased stiffness and durability. Excellent for high-end displays, mounting, and exhibits where flatness matters.

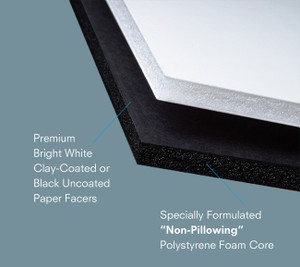

Paper-Faced Foamboard (Fome-Cor)

Economical, lightweight choice for indoor mounting, posters, and short-term signage. Smooth paper facers accept inks, adhesives, and laminates; not intended for humid or outdoor environments.

Self-Adhesive, Fire-Rated & Colored Options

Available with pressure-sensitive adhesive liners for quick mounting, colored cores and facers for creative applications, and select ratings for code-driven spaces. Check specifications per SKU.

Foam Boards — Quick Facts

| Surfaces | Smooth print-ready facers for UV, latex, screen print, vinyl, and mounting films (verify per product) |

|---|---|

| Thicknesses | Common: 3 mm, 5 mm, 6 mm, 10 mm (≈ 1/8″, 3/16″, 1/4″, 3/8″); heavier gauges available by SKU |

| Rigidity | Gatorfoam > Foam PVC > Paper-faced foamboard (general rule) |

| Moisture resistance | Foam PVC good; Gatorfoam moderate; paper-faced foamboard indoor-only |

| Finishing | Cut, route, V-groove, laminate, mount; use sharp blades and backing boards for clean edges |

| Mounting | PSA liners, spray adhesives, or cold laminators; consider expansion and humidity control |

How to Choose the Right Foam Board

- Use foam PVC for durable indoor signs and moderate-term displays; limited outdoor/sheltered installations with proper preparation.

- Choose Gatorfoam for maximum stiffness, flatness, and premium presentation quality.

- Select paper-faced foamboard for economical, short-term indoor mounting and presentations.

Handling & Finishing Tips

- Score lightly and make multiple passes with fresh blades to prevent tear-out.

- Use cold-mount films or PSA boards to minimize warping and bubbles.

- Store flat and condition materials to room humidity before mounting or printing.

Foam Boards – FAQs

Can foam PVC be used outdoors?

Foam PVC can be used for certain short- to mid-term outdoor or sheltered applications. Verify the specific product’s outdoor rating, paint/ink system, and installation details.

What’s the difference between Gatorfoam and paper-faced foamboard?

Gatorfoam uses dense facers for higher stiffness and durability, ideal for premium displays. Paper-faced foamboard is lighter and economical for short-term indoor mounting.

How do I prevent warping or bubbles when mounting prints?

Use clean, dust-free surfaces, apply even pressure, and consider PSA boards or cold laminators. Allow materials to acclimate before mounting.

Can these boards be routed or V-grooved?

Yes. Foam PVC and Gatorfoam can be routed and V-grooved with appropriate tooling and feeds. Paper-faced foamboard should be cut with sharp blades and backing boards.

Do you offer cut-to-size and finishing services?

Yes. Laird Plastics provides cut-to-size, routing, laminating, and mounting services. Contact us for a quote.

Need Foam Boards Cut to Size?

Work with Laird Plastics to select foam PVC, Gatorfoam, or paper-faced foamboard and have it delivered to spec—ready for print, mounting, or installation.