Acrylic

Acrylic Plastic Sheets & Materials — Clear, Durable & Fabrication-Ready

Explore Laird Plastics’ acrylic selection for signage, display, glazing, and creative builds. Acrylic delivers up to 92% light transmission, excellent clarity, and impact resistance far exceeding standard glass—available in cast, extruded, and specialty grades, plus rod & tube.

Use when you need: optical clarity, low weight, clean edges (laser/CNC), outdoor-capable grades.

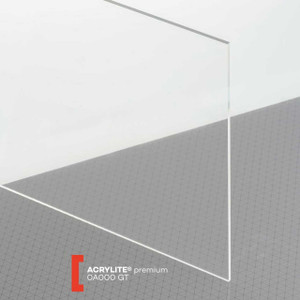

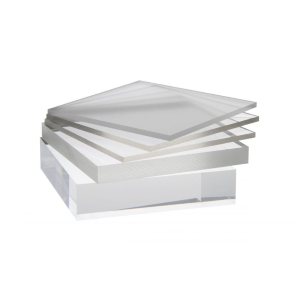

Cast Acrylic Sheets (Cell-Cast)

Premium clarity and surface finish. Excellent for laser cutting, polishing, machining, and thermoforming. Ideal where optical quality and crisp edges matter.

Extruded Acrylic Sheets

Cost-effective with consistent thickness. Great for sign faces, frames, POP displays, and general-purpose glazing on flat or gentle curves.

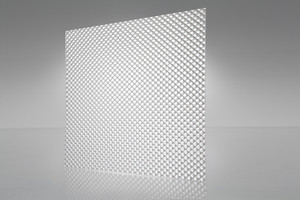

Mirror, Non-Glare & Light-Diffusing Acrylic

Enhance function and aesthetics: acrylic mirror for light weight reflection, non-glare for displays, and LED diffusers for even illumination.

Acrylic Rod & Tube

Clear rod and tube for displays, guards, lighting, and architectural features. Strong, polishable, and available in multiple diameters and wall thicknesses.

Acrylic at a Glance — Quick Facts

| Light transmission | ≈ 92% (clear grades) |

|---|---|

| Impact vs. glass | Up to ~17× more impact resistant |

| Available forms | Sheets, rod, tube |

| Thickness range | ≈ 0.060″ to 1″+ (by SKU) |

| Finishes & colors | Clear, colors, mirror, non-glare, matte, prismatic/diffusing |

| Fabrication | Cut, CNC, laser (cast), drill, bend, thermoform, polish |

| Outdoor use | UV-capable grades available; verify warranty/spec |

Cast vs. Extruded — How to Choose

- Cast: Best clarity & polishability; excels in laser cutting, edge finishing, and thermoforming.

- Extruded: Budget-friendly, consistent thickness; ideal for signage & POP on flat/simple curves.

Where Each Type Shines

- Specialty acrylic: Mirror for lightweight reflection; non-glare for framed art/displays; diffusers for LED lighting.

- Rod & Tube: Guards, retail displays, lighting columns, architectural accents.

Acrylic – FAQs

Is acrylic the same as plexiglass?

“Plexiglass” is a common name for acrylic (PMMA). They refer to the same plastic family.

Can acrylic be used outdoors?

Yes—choose UV-resistant grades designed for weather exposure and color stability.

What’s the difference between cast and extruded acrylic?

Cast provides superior clarity and polishability for premium finishes; extruded delivers consistent thickness at a lower cost.

How do I clean acrylic without scratching it?

Use mild soap and water with a soft microfiber cloth; avoid ammonia-based cleaners and harsh abrasives.

Do you offer cut-to-size acrylic?

Yes. Laird Plastics can cut, polish, and fabricate to your specifications. Contact us for a quote.

Need Acrylic Cut to Size?

From clear glazing to specialty displays, Laird Plastics can help you select the right acrylic and deliver precision-cut parts.