FOME-COR® Foam Board - The Original Graphic Arts Foam Board

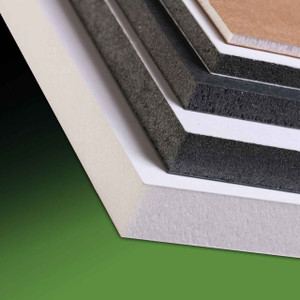

Featuring a proprietary extruded polystyrene foam core sandwiched between bright white double clay‑coated or black uncoated paper facers, this versatile material delivers exceptional performance for a wide range of short‑term display applications.

Renowned for its extreme lightweight properties, superior fabrication capabilities, and excellent printability, FOME-COR® delivers professional‑quality results for retail displays, exhibits, framing, and signage. The unique manufacturing process creates a foam core that remains unrivaled in cutting precision and fabrication versatility, offering both pillowing and recovery variations to suit your specific project requirements.

For detailed technical specifications, please refer to our Technical Data Sheet.

Why Choose FOME-COR® Over Other Foam Board Materials?

- Industry‑Leading Performance: The original foam board trusted by graphic arts professionals for over six decades.

- Superior Print Surface: Bright white, clay‑coated paper facers deliver exceptional color reproduction for vibrant graphics.

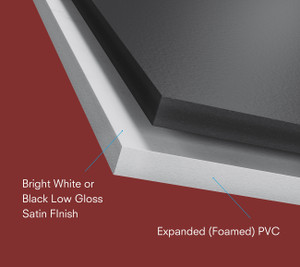

- Unique Die‑Cutting Properties: Produces a permanently closed, compressed edge when die‑cut for professional displays.

- 3D Capabilities: Can be embossed to create distinctive three‑dimensional effects unattainable with other substrates.

- Versatile Fabrication: Cuts easily and cleanly, even by hand, with minimal tooling requirements.

- Multiple Size & Thickness Options: Available in various dimensions and thicknesses to suit virtually any project need.

Features & Benefits

- Exceptionally Lightweight: Easy to handle, transport, and install while maintaining structural rigidity.

- Superior Printability: Bright white clay‑coated facers ensure vibrant, sharp graphics for digital and screen printing.

- Easy Fabrication: Cuts cleanly with standard tools—even by hand—without specialized equipment.

- Unique Die‑Cutting: Proprietary core creates clean, compressed edges that eliminate the need for edge finishing.

- 3D Embossing Effects: Pillowing properties enable distinctive embossed textures for added visual interest.

- Eco‑Conscious Materials: Paper facers sourced from Sustainable Forestry Initiative (SFI)‑certified suppliers.

- Multiple Thickness Options: 1/8″ (3.2 mm), 3/16″ (4.8 mm), 3/8″ (10 mm), 1/2″ (13 mm).

- Variety of Sheet Sizes: From 20″×30″ up to 60″×120″, with custom sizes available.

- Made in the USA: Manufactured with over 60 years of foam board expertise.

- Color Options: Bright white or black facers to suit different design requirements.

Technical Specifications

| Material Composition | Extruded polystyrene foam core with paper facers |

|---|---|

| Facer Options | Bright white double clay-coated or black uncoated paper |

| Standard Thicknesses | 1/8″ (3.2 mm), 3/16″ (4.8 mm), 3/8″ (10 mm), 1/2″ (13 mm) |

| Standard Sheet Sizes | 20″×30″, 24″×36″, 30″×40″, 32″×40″, 40″×60″, 48″×96″, 60″×120″ |

| Weight | Extremely lightweight (varies by thickness) |

| Cutting Properties | Cuts easily with knife, scissors, die‑cutter; compressed edge when die‑cut |

| Print Compatibility | Digital printing, screen printing, direct printing with various ink types |

| Indoor Use | Indoor applications only |

| Application Lifespan | Short‑term (recommended for temporary displays) |

| Sustainability | Paper facers sourced from SFI or Forest Management Certified suppliers |

Applications

Retail Point‑of‑Purchase Displays

- Create attention‑grabbing signage and free‑standing units with easy installation and repositioning flexibility.

Trade Show & Exhibition Displays

- Lightweight, transportable exhibit components that maintain a professional appearance throughout events.

Interior Signage

- Cost‑effective directional signs and temporary announcements with excellent readability and color reproduction.

Framing & Mounting Applications

- Ideal for mounting photos and artwork; FOME-COR® FOUNDATION variant offers acid‑free facers for archival preservation.

3D Dimensional Displays

- Embossed effects add depth and visual interest unattainable with flat substrates.

Educational & Presentation Boards

- Professional materials for school projects and presentations, cutting cleanly for precise custom sizes.

Printing & Fabrication Capabilities

Printing Options

- Digital Direct Printing: Optimal surface for UV flatbed printing, ensuring vibrant, sharp details.

- Screen Printing: Maintains dimensional stability and accurate registration.

- Mounting Graphics: Ideal substrate for adhesive mounting of printed media.

- Surface Painting: Compatible with acrylics, poster colors, and latex-based paints.

Fabrication Techniques

- Hand Cutting: Quick prototypes and small runs with utility knives or scissors.

- Die Cutting: Compressed, closed edges maintain form without additional finishing.

- Embossing: Create three-dimensional textures and relief effects.

- Scoring & Folding: Clean fold lines for self‑standing displays without delamination.

Installation & Handling Recommendations

Handling & Storage

- Flat Storage: Store sheets flat to prevent warping; avoid heavy loads on stored sheets.

- Climate Control: Maintain stable temperature and humidity to preserve dimensional stability.

- Clean Handling: Wear gloves to keep facers free of oils and dirt.

Installation Guidelines

- Mounting Options: Use removable adhesive strips, Velcro®, or pushpins based on display weight.

- Edge Finishing: Hand‑cut edges can be trimmed or taped for a polished look.

- Support Points: Reinforce larger panels to prevent sagging, especially in humid environments.

- Indoor Use Only: Not suitable for outdoor exposure; see GATORPLAST® or DIBOND® for weather‑resistant alternatives.

Frequently Asked Questions About FOME-COR® Foam Board

How does FOME-COR® compare to other foam board products?

Is FOME-COR® suitable for outdoor applications?

What is the difference between FOME-COR® and FOME-COR® with ENCORE® TECHNOLOGY?

What printing methods work best with FOME-COR®?

Resources

View Sales Sheet

View Fabrication Guide

View Safety Data Sheet

- Material:

- Foam Board

- Form:

- Sheet