GATOR® Heavy-Duty Foam Board - Industry-Leading Rigid Substrates for Premium Display Applications

What is GATOR® Heavy-Duty Foam Board?

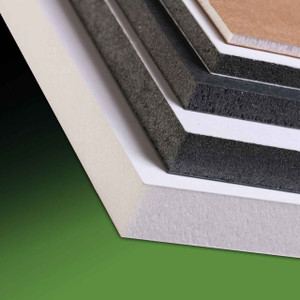

The GATOR® product line represents the industry's leading heavy‑duty foam boards, setting the standard for superior rigidity, printability, and durability in demanding display applications for over 30 years. This premium collection from 3A Composites features extruded polystyrene foam cores combined with various high‑performance facers, creating rigid yet lightweight substrates that excel in structural strength while maintaining exceptional fabrication versatility.

The GATOR® Product Family: Engineered for Performance

- GATORFOAM®: Original heavy‑duty graphic arts board with wood‑fiber veneers for maximum rigidity and dent resistance.

- GATORFOAM® PRO: Enhanced version with proprietary surface treatment for superior ink adhesion and printability.

- GATORFOAM® EXTERIOR: Top‑grade adhesives and formulation to withstand outdoor conditions.

- GATORFOAM® SELF-ADHESIVE: One veneer coated with pressure‑sensitive adhesive for easy mounting.

- GATORPLAST®: Polystyrene foam core with high‑impact polystyrene facers for water resistance and vinyl graphics.

- GATORBLANKS®: Pure extruded polystyrene panels without facers, ideal for dimensional letters and custom fabrication.

Features & Benefits

- Exceptional Rigidity: Maintains flatness and structural integrity even in large formats, preventing warping or bowing.

- Superior Printability: Engineered facers provide excellent ink adhesion and vibrant color reproduction.

- Outstanding Durability: Highly resistant to dents and scratches in high‑traffic environments.

- Lightweight Construction: Simplifies handling, installation, and shipping compared to wood or metal alternatives.

- Excellent Fabrication: Cuts, routes, drills, and shapes cleanly with standard woodworking tools.

- Versatile Mounting: Compatible with adhesives, mechanical fasteners, and mounting systems.

- Multiple Thicknesses: Ranges from 3/16″ to 3″ to meet structural and aesthetic needs.

- Water Resistance: GATORPLAST® variant protects against moisture damage for humid or temporary outdoor use.

- Broad Size Range: Standard sheets up to 60″×120″; custom sizes available.

- Made in the USA: Manufactured in 3A Composites’ American facilities with rigorous quality control.

Technical Specifications

| Specification | GATORFOAM® | GATORFOAM® PRO | GATORPLAST® | GATORBLANKS® |

|---|---|---|---|---|

| Core Material | Extruded polystyrene foam | Extruded polystyrene foam | Extruded polystyrene foam | Extruded polystyrene foam (no facers) |

| Facer Material | Wood‑fiber veneer | Wood‑fiber veneer + treatment | High‑impact polystyrene | None |

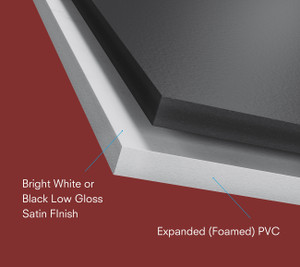

| Available Colors | Bright white, black | Bright white | White, black | White, black |

| Thicknesses | 3/16″–3″ | 3/16″, 1/2″ | 3/16″–3″ | 3/4″–3″ |

| Sheet Sizes | 48″×96″, 60″×120″ | 48″×96″ | 48″×96″ | 48″×96″ |

| Print Compatibility | Digital UV, screen, painting | Enhanced digital UV, screen, painting | Digital UV, screen, vinyl | Requires coating/painting |

| Outdoor Durability | Limited (≥1″ with edge protection) | Limited | Better moisture resistance | Requires protective coating |

| Cutting Methods | Saw, router, CNC | Saw, router, CNC | Knife, saw, router, CNC | Knife, saw, router, hot wire |

| Heat Formability | Limited | Limited | Good | Excellent |

Applications

- Premium Signage: Flatness and rigidity ideal for high‑end interior signage and wayfinding.

- Exhibition & Trade Shows: Transportable, reusable displays that withstand multi‑event handling.

- Retail Merchandising: Durable window and in‑store graphics for high‑traffic areas.

- Photo & Art Mounting: Superior flatness for archival‑quality artwork displays.

- Dimensional Letters & Logos: Thick panels for three‑dimensional signage elements.

- Museum & Gallery: Professional‑grade displays with long‑term durability.

GATOR® Product Line Detailed Description

GATORFOAM®

Extruded foam core bonded to wood‑fiber veneers for extreme rigidity, dent resistance, and bright white printing surface.

Key Features:

- Maximum structural strength

- Bright white veneer

- 3/16″–3″ thickness

- Woodworking tool fabrication

GATORFOAM® PRO

All the strength of GATORFOAM® with a proprietary surface treatment for superior ink adhesion and color fidelity.

Key Features:

- Enhanced print surface

- Static resistance

- 3/16″, 1/2″ thickness

- Improved scratch resistance

GATORPLAST®

Polystyrene facers over foam core for water resistance and vinyl graphic application in humid or short‑term outdoor use.

Key Features:

- Water‑resistant facers

- Vinyl adhesion

- Knife cutting

- Smooth surface

GATORBLANKS®

Pure foam panels without facers, perfect for dimensional letters and custom fabrication.

Key Features:

- 3/4″–3″ thickness

- Hot wire and knife cutting

- Lightweight

- Paintable

Printing & Fabrication Capabilities

Printing Options

- Digital UV Printing: All GATOR® facers accept direct UV printing; PRO variant optimized for detail and adhesion.

- Screen Printing: Stable surfaces yield vibrant spot and multi‑color prints.

- Vinyl Application: GATORPLAST® offers repositionable vinyl adhesion.

- Painting: GATORFOAM® variants accept water‑based and select solvent paints; PLAST and BLANKS require compatible paint systems.

Fabrication Techniques

- Cutting & Routing: Table saws, routers, CNC yield clean edges on faced products; knife cutting available on PLAST and BLANKS.

- Edge Finishing: Sanding, painting, or edge banding for exposed edges.

- Mounting & Laminating: Compatible with adhesives and tapes; SELF‑ADHESIVE variant for easy mounting.

- Assembly: Use mechanical fasteners or adhesives for complex structures.

Installation & Handling Recommendations

Storage & Handling

- Flat Storage: Prevent warping by storing sheets flat with full support.

- Temperature: Keep below 165°F (74°C) for polystyrene facers.

- Large Sheets: Use proper support and lifting techniques.

Installation Guidelines

- Hardware: Pre‑drill for mechanical fasteners.

- Adhesives: Match adhesive to facer type.

- Edge Protection: Paint or band edges on EXTERIOR variant for UV protection.

Outdoor Considerations

- EXTERIOR: Suitable for ≥1″ thickness outdoors with edge treatments.

- Weather Protection: Use coatings or design to minimize direct exposure.

- Drainage: Prevent water accumulation against boards.

Frequently Asked Questions About GATOR® Products

What is the main difference between GATORFOAM® and GATORPLAST®?

How does GATORFOAM® PRO differ from standard GATORFOAM®?

Can GATOR® products be used outdoors?

What cutting methods work best?

Create Premium Displays with GATOR® Heavy-Duty Foam Boards

Whether you're designing high‑end signage, exhibition graphics, retail displays, or dimensional elements, GATOR® products provide the professional performance and versatility to bring your vision to life with exceptional quality and durability.

Contact your Laird Plastics representative today to discuss your specific project requirements and discover which GATOR® product is the ideal solution for your graphic display, signage, or fabrication application.

Resources

View Sales Sheet

View Fabrication Guide

View Safety Data Sheet

- Material:

- Foam Board

- Form:

- Sheet