SINTRA® Expanded PVC Board - The Industry Standard for Premium Rigid Substrates

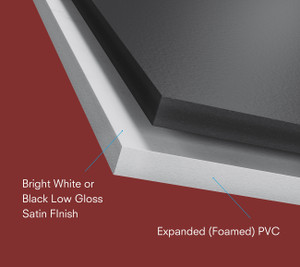

Made from moderately expanded, closed-cell polyvinyl chloride (PVC) with a low-gloss satin finish, this premium rigid substrate delivers exceptional performance for demanding signage, display, and fabrication applications.

Engineered to outperform conventional PVC materials, SINTRA® offers outstanding print results and enhanced durability for mounting and dimensional graphics. Its closed-cell structure balances lightweight handling with rigid strength, making it the preferred choice of designers, fabricators, and sign makers for premium displays.

The SINTRA® Collection: Four Product Lines for Every Application

- SINTRA® Original: Premium high-performance PVC board for applications demanding superior printability and durability.

- SINTRA® VERS: Lighter weight board optimized for general-purpose and high-volume jobs with fast turnaround.

- SINTRA® ECLIPSE: White surface over black core for elegant, no-edge-finishing displays.

- SINTRA® CONSTRUCT: Enhanced rigidity and screw retention for mechanical assembly and fixtures.

Features & Benefits

- Premium Bright Surface: Low-gloss satin finish delivers accurate color reproduction for digital and screen printing.

- Superior Durability: Excellent dent and scratch resistance for high-traffic and demanding environments.

- Lightweight Yet Rigid: Closed-cell structure balances ease of handling with structural strength.

- Heat Formable: Creates dramatic 3D shapes without compromising surface quality.

- Chemical Resistance: Withstands moisture, acids, bases, and common cleaning agents.

- Consistent Quality: Manufactured to tight tolerances for flat, even sheets.

- Excellent Machinability: Cuts, routes, drills, and fabricates with standard woodworking tools.

- Fire Performance: Self-extinguishing; Class A (ASTM E-84) in gauges ≤ 5 mm.

- Color Options: Standard bright white and black; custom colors available.

- Made in the USA: Produced at 3A Composites USA facilities with four decades of expertise.

Technical Specifications

| Specification | Details |

|---|---|

| Material Composition | Moderately expanded, closed-cell PVC |

| Surface Finish | Low-gloss satin |

| Available Colors | Bright white, black; custom colors |

| Thicknesses (Original) | 1 mm, 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 10 mm, 12.7 mm |

| Thicknesses (VERS) | 3 mm – 6 mm |

| Thicknesses (ECLIPSE) | 3 mm, 6 mm, 12.7 mm |

| Thicknesses (CONSTRUCT) | 6 mm, 10 mm, 13 mm, 19 mm |

| Sheet Sizes | 48″×96″, 60″×120″, 2 m×120″ (varies by line) |

| Density | ~0.55–0.75 g/cm³ |

| Fire Rating | Class A (ASTM E-84) in gauges ≤ 5 mm |

| Max Service Temp | 140°F (60°C) |

| Heat Forming Temp | 240°F–320°F (115°C–160°C) |

| Print Compatibility | Digital UV, screen printing, vinyl application |

| Chemical Resistance | Excellent vs. moisture, acids, bases, cleaning agents |

| UV Resistance | Good for indoor; limited outdoor |

Applications

- High-End Signage: Premium interior/exterior signs with vibrant graphics and professional finish.

- Retail POP/POS Displays: Lightweight structural displays for counters and freestanding units.

- Exhibition Graphics: Transportable panels that withstand multi-day events.

- 3D Displays: Heat-formed shapes for environmental graphics and dimensional logos.

- Fixtures & Kiosks: SINTRA® CONSTRUCT variant for screw-retained retail fixtures.

- Museum & Gallery: Archival-quality displays with exceptional visual clarity.

Printing & Fabrication Capabilities

Printing Options

- Digital UV: Exceptional color gamut and adhesion on satin surface.

- Screen Printing: Sharp detail, vibrant spot and multi-color designs.

- Vinyl Application: Smooth surface for strong vinyl adhesion.

- Painting: Accepts acrylics and specialized sign paints.

Fabrication Techniques

- Cutting & Routing: Clean edges with table saws, panel saws, CNC routers.

- Heat Forming: Mold curves/shapes at 240°F–320°F (115°C–160°C).

- Drilling & Fastening: Pre-drill for screws; CONSTRUCT optimized for retention.

- Laminating & Mounting: Bond sheets or apply adhesives and tapes.

- Edge Finishing: Route, sand, or paint edges for polished look.

Frequently Asked Questions About SINTRA® Expanded PVC

How does SINTRA® compare to other PVC brands?

As the original expanded PVC with 30+ years’ leadership, SINTRA® offers uniform cell structure for superior printability, durability, and dimensional stability versus generic alternatives.

What are the four SINTRA® product lines?

The SINTRA® Collection includes ORIGINAL (premium), VERS (lightweight), ECLIPSE (white over black), and CONSTRUCT (mechanical assembly)—each engineered for distinct applications.

Is SINTRA® suitable outdoors?

Designed primarily for interior use; suitable for short-term outdoor. For extended outdoor, apply UV-resistant coatings or choose exterior-rated materials like DIBOND®.

Which printing methods work best?

Direct UV printing delivers top performance on the satin surface; screen printing and vinyl application also yield excellent results. Ensure clean surface before printing.

Resources

View Sales Sheet

View Fabrication Guide

View Safety Data Sheet

Cutting Guide

Cleaning Instructions

UL Certification

- Material:

- PVC Foam

- Form:

- Sheet