PVC Foam

PVC Foam Sheets (Expanded PVC) — Lightweight, Rigid & Print-Ready

Laird Plastics supplies expanded PVC sheets—often called foam PVC—for signage, retail fixtures, exhibits, POP displays, and fabrication. These closed-cell sheets feature smooth, matte surfaces for direct print and vinyl, are easy to machine and bond, and offer excellent dimensional stability at a low weight. Cut-to-size and custom fabrication available.

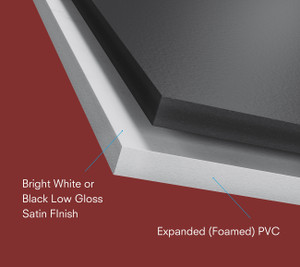

Standard PVC Foam Sheets

Balanced density for stiffness and easy processing. Ideal for indoor signs, wall panels, and dimensional display elements with crisp edges and a matte finish.

High-Density / Premium Print Surfaces

Higher density for improved edge quality, screw retention, and surface finish. Optimized for direct-to-substrate UV and latex printing and fine detail routing.

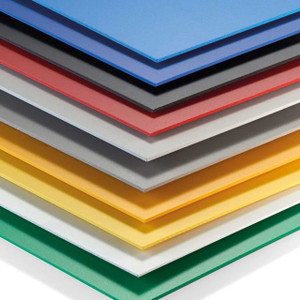

Colored, Gloss & Specialty Options

Factory tints and finishes reduce paint steps and streamline brand consistency. Select gloss, matte, or textures to match application and durability needs.

Cut-to-Size & Assembly

CNC routing, V-grooving, heat-forming, solvent bonding, and mechanical fastening. Delivered kitted or assembled to accelerate installation.

PVC Foam — Quick Facts

| Surface | Smooth, matte print facers; accepts UV/latex/screen inks and vinyl |

|---|---|

| Thicknesses | Common: 3 mm, 5 mm, 6 mm, 10 mm; additional gauges by SKU |

| Weight | Lower than solid PVC or acrylic; easy handling and installation |

| Machining | Score/cut, CNC route, drill, V-groove, heat-form; bonds with solvent/adhesive |

| Moisture & Chemicals | Closed-cell structure resists moisture; good chemical cleanability indoors |

| Use Environment | Best for indoor and sheltered outdoor; verify UV/weather ratings for exterior installs |

Expanded PVC vs. Foam Board vs. Solid PVC

- Expanded PVC: Lightweight, rigid, print-ready; great balance of cost, finish, and fabrication ease.

- Paper-Faced Foam Board: Lighter and cheaper; indoor-only and less durable for long-term installs.

- Solid PVC (Rigid): Heavier, tougher, and more weatherable; choose when higher impact or exterior duty cycles are required.

Application Tips

- Acclimate sheets to print room temperature/humidity to minimize warp.

- Use sharp tools and multiple light passes for clean edges on thin gauges.

- For outdoor use, select grades specified for weatherability and use appropriate paints/laminates.

PVC Foam – FAQs

Can PVC foam be used outdoors?

Some grades perform in sheltered outdoor installs; for long-term exterior exposure, confirm UV/weather ratings or consider solid PVC or other exterior-rated substrates.

Is expanded PVC good for direct printing?

Yes. The smooth matte surface is optimized for UV, latex, and screen printing. Clean with isopropyl/water (per ink supplier guidance) before printing.

Can it be heat-formed or bent?

Yes. Expanded PVC can be heat-formed and V-grooved for clean folds; use controlled temperatures to prevent surface glossing.

How do I bond or fasten expanded PVC?

Use compatible solvent cements or structural adhesives; mechanical fastening is possible with appropriate pilot holes and screws.

Do you offer cut-to-size and fabrication?

Yes—Laird Plastics provides cut-to-size, routing, V-grooving, heat forming, and assembly. Contact us for a quote.

Need PVC Foam Sheets Cut and Ready to Install?

From retail signage to exhibit builds, Laird Plastics can recommend the right density and finish, then deliver parts to spec—fast.